When inside the producing spot, the materials are transferred by way of corridors for the designated procedure suite. In case the operation in the process suite just isn't “shut”, exactly where one particular side with the room is open up on the setting, the airflow will shift in the room to protect the adjacent space or corridor from contamination.

Supplies that involve Particular circumstances, for instance vacant capsule shells and hygroscopic powders, are saved in an area which is designed to keep up temperature and relative humidity requirements.

As we technique 2025, we could hope to determine far more customized and adaptive training systems that use info analytics to discover unique learning needs and tailor schooling content accordingly.

1 crucial development is the shift towards more frequent and extensive environmental checking. Regulators expect pharmaceutical firms to put into action sturdy checking programs that can detect and reply to contamination functions in serious-time.

No matter if developing a new facility or upgrading your present a person, your venture involves watchful thing to consider. Our companies include things like:

Efficient system circulation demands safe and trusted solution transfer tools. To aid sustain merchandise integrity and support be certain product handling security and performance, FARRAR gives conventional and personalized product handling devices for producing process demands.

These techniques let For additional specific temperature and force Command, ensuring reliable sterilization success although minimizing energy usage.

Particulate Subject: Dust, fibers, and other particles which could compromise the standard of a drug or reduce the effectiveness of the filter or drug-shipping and delivery program.

The autodefrost location for your 4000 Sequence Controlled Price Chamber is really a guide course of action; The user will start off the defrost approach with a thrust button at the conclusion of each of each and every freeze process.

These info underscore the value of very good personal hygiene along with a thorough focus to element in the aseptic gowning procedure utilized by staff coming into the managed ecosystem. The moment these staff are appropriately gowned—which includes complete facial coverage—they need to be mindful to keep up the integrity of their gloves and fits constantly.

Sieve Impactor— The equipment is made up of a container designed to support a Petri dish containing a nutrient agar. The duvet with the device is perforated, Together with the perforations of a predetermined dimensions. A vacuum pump draws clean room layout pharmaceutical a known volume of air with the deal with, and the particles from the air containing microorganisms effect on the agar medium inside the Petri dish.

Gelatin Filter Sampler— The unit is made of a vacuum pump using an extension hose terminating inside of a filter holder which can be Positioned remotely in the vital House. The filter is made of random fibers of gelatin capable of retaining airborne microorganisms.

Isolator methods require fairly rare microbiological monitoring. Steady total particulate monitoring can provide assurance which the air filtration click here technique within the isolator is Operating correctly. The solutions for quantitative microbiological air sampling described During this chapter may not have sufficient sensitivity to test the environment within an isolator.

INTERPHEX, the top worldwide pharmaceutical and biotechnology party that fuses industry innovation with qualified-led convention.

Jason J. Richter Then & Now!

Jason J. Richter Then & Now! Lark Voorhies Then & Now!

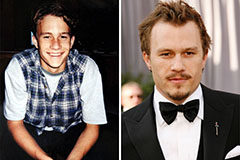

Lark Voorhies Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Barbi Benton Then & Now!

Barbi Benton Then & Now! Jaclyn Smith Then & Now!

Jaclyn Smith Then & Now!